what are nanobubbles?

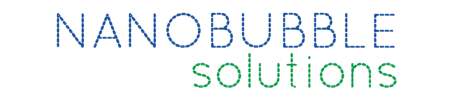

Nano or ultrafine bubbles have a diameter of less than 50 microns and unique physical characteristics that differ from other types of bubbles.

They are too small to rise up through liquid and get compressed by negative ions at the gas-liquid interface so don’t combine to form larger bubbles. This means they remain in liquid for a long time. They then shrink leaving their entire gas load in the liquid.

Nanobubbles were first discovered in 1894 when the Royal Navy was testing a high speed torpedo boat. Lord Rayleigh, the legendary classical physicist, investigated further and discovered that micro nanobubbles collapsed and generated high levels of heat and pressure.

Nanobubbles have previously been produced in a variety of cumbersome and expensive ways. However now, a new, unique carbon ceramic technology, which works by osmosis, supersedes everything that has gone before. Using only a fraction of the energy required by other methods, this technology, invented by Nanobubble Solutions Limited (NBS) co-owner and company director Satoshi Anzai, can be used for a far greater number of applications and produces double the number of bubbles achieved by any other system.

the material/units

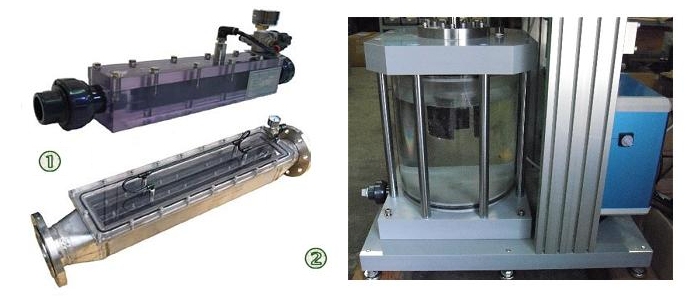

Carbon ceramic looks and feels like a smooth stone. Gas is placed into the diffuser head at 29psi pressure (or less) and exits from the whole surface of the diffuser head by osmosis. The gas is picked up, as nanobubbles, as the liquid passes through the unit. The standard range of in-Line generators come in different sizes to accommodate different volumes of liquid in order to guarantee the 90% gas transfer rate at that scale of operation. Diffuser heads are either small nozzle type or plate type (1 below). We will also design to order and offer rotary/propeller type diffusers that operate directly in liquid (2 below).

1

PLATE TYPE

with pressure gauge

PLATE TYPE

with pressure gauge

2

ROTARY TYPE

(sample test tank)

ROTARY TYPE

(sample test tank)

benefits of this technology

| works by osmosis with no mechanical parts |

| can place any gas into any liquid |

| gas remains in liquid and in ONE PASS guarantees a 90% gas transfer/saturation rate (double any other system) |

| works on very low pressure, maximum 29psi |

| operational in high temperatures |

| extremely low energy requirement so outstanding cost effectiveness |

| can place nanobubbles into liquids of high viscosity (think mayonnaise) |

| can easily up-size to large scale production without increase in pressure or energy |

| in-line, rotary/propeller and ultrasonic methods of delivery - making nanobubbles available to a far greater number of industries (for example pharmaceutical and mining/ferric leaching) |

| replaces or reduces need to use chemicals, so more environmentally friendly |

| electrical charge and high frequency induction heating allowed |

patent protection

Developed over a number of years, Mr Anzai has successfully registered patents in Japan, the US (no 8,919,747 B2) and Europe for his carbon ceramic technology. Nanobubble Solutions Limited (NSL), is part-owned by Mr Anzai and he is also a director of the company which has secured the right to develop and market the technology in the USA, Europe and the Middle East along with certain other English speaking territories around the world.

find out more

Find out more about how this exciting new technology is being used on our applications page. There's more about our business here. If you are a business interested in exploring our technology then please contact us.

Copyright © 2026 Nanobubble Solutions Limited

web site by Shepperton Software

web site by Shepperton Software